Floating Slab vs. Monolithic Slab: Key Differences

Every build depends on a strong, reliable foundation. Before the concrete is poured you need to decide if you’ll use a floating slab foundation or a monolithic slab foundation. The choice you make affects how the slab resists soil pressure, frost movement and structural load bearing.

A floating slab is poured onto a compacted gravel base without deep footings, which is used for garages, small home additions or other light structures. A monolithic slab combines the slab and footing in one continuous pour, forming a thick edge that supports heavier construction such as pole barns and workshops.

This article explains the key differences between floating and monolithic slabs, helping you choose the best foundation for your design and conditions.

What Is a Floating Slab Foundation?

A floating slab foundation is a reinforced concrete base, usually 4 to 6 inches thick, poured over compacted gravel. It’s called “floating” because it isn’t anchored to deep footings — thick, load-bearing concrete strips — that extend below the frost line. Instead, it rests directly on the ground, allowing for slight movement as the soil expands or contracts.

This setup works well for detached garages, small home additions like sunrooms or mudrooms, and similar builds where excavation isn’t practical.

What Is a Monolithic Slab Foundation?

A monolithic slab foundation is poured all at once with the slab and footing formed together in a single pour. The outer edges are dug deeper and reinforced with rebar to act as footings, while the center remains thinner to maintain the standard floor thickness. This method locks the entire base into one solid mass of concrete, creating strong perimeter support without the need for separate footing forms or multiple pours.

The center of the monolithic slab is about 4 inches thick, and the perimeter is thickened to 10 to 12 inches, depending on the wall load and soil bearing strength. Builders prefer this approach for pole barns, workshops, small commercial spaces and single-story homes that need a durable, load-bearing foundation.

Key Differences Between Floating and Monolithic Slabs

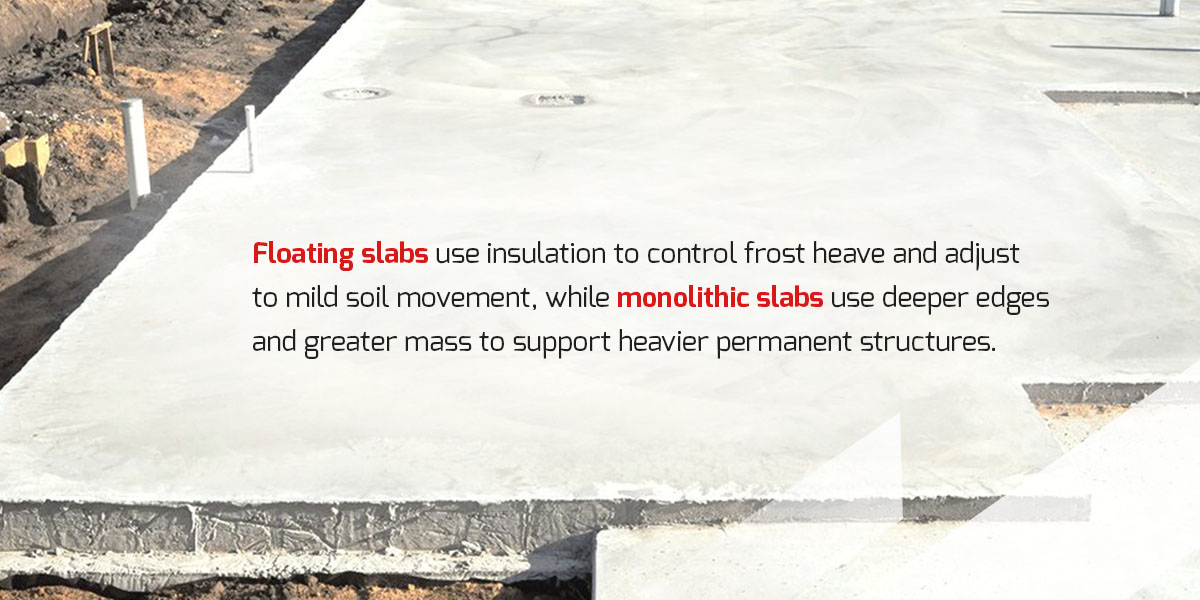

Monolithic and floating slabs differ in performance, as floating slabs use insulation to control frost heave and adjust to mild soil movement, while monolithic slabs use deeper edges and greater mass to support heavier permanent structures. Here’s a breakdown of their key differences:

| Type | Floating Slab Foundation | Monolithic Slab Foundation |

| Thickness | Uniform 4 to 6 inches across the slab, poured over compacted gravel. | A 4-inch center with a 10-to-12-inch thickened perimeter that acts as a footing. |

| Frost Protection | Uses frost-protected shallow foundation (FPSF) with insulation under or around the slab to prevent soil freezing. | Footings are protected from frost by extending below the frost line or adding engineered insulation to meet the codes. |

| Pour Method | Single pour for the slab only, no structural footing. | One continuous pour where the slab and footing are formed and poured together. |

| Build Timeline | Faster installation — the project can be completed in a few days with limited excavation. | Takes a little longer due to excavation and site preparation. |

| Soil Adaptability | More adaptable to unstable and shifting soil. It moves with soil shifts, which helps reduce cracking. | Better suited for firm, stable soils, providing a more fixed and durable foundation. |

| Load-Bearing Capacity | Supports lighter structures due to its limited load-bearing capacity. | Has a much larger load-bearing capacity that’s suitable for heavier structures. |

| Repair Complexity | Easier to fix or patch as there’s no integrated footing. | Harder to repair due to integrated footing and single-pour construction. |

| Cost | Floating slab costs are usually lower ($4 to $5 per square foot) because the build needs less excavation and concrete. | Monolithic slab costs are higher (around $6 to $12 per square foot or more) because the pour needs more concrete and preparation. |

Floating Slab Pros and Cons

A floating slab foundation uses insulation but supports only light loads and depends on proper drainage and compaction.

Here are the main benefits of floating slabs:

- Performs well in cold climates with proper insulation

- Simple design that limits material waste

- Easier to modify or extend later

- Lower site impact and minimal excavation work

Floating slabs can have some disadvantages, such as:

- Insulation and vapor barriers must be carefully installed

- Poor drainage can shorten the lifespan

- Not suited to steep or heavily shifting terrain

Monolithic Slab Pros and Cons

A monolithic slab foundation provides strong load support and quick installation. However, it requires stable soil and precise grading, and repairs are difficult once poured.

These are the benefits of monolithic slabs:

- Strong perimeter edge resists settling and cracking

- Single pour reduces construction joints and leaks

- Works well for heated spaces and radiant floor systems

- Provides clean, open floor space with no interior footing lines

Here are some potential downsides of using monolithic slabs:

- Requires precise grading and compaction before pouring

- Limited frost protection without insulation or deep edges

- Repairs can be costly due to the integrated footing design

When to Choose a Floating Slab

The best use cases for floating slab construction include greenhouses, patio enclosures, storage buildings and small accessory dwellings. Its shallow design works well for lightweight structures that need a stable surface without full excavation.

Floating slabs are also practical for utility spaces like pump houses or garden studios, where temperature control and ground stability matter. With proper insulation and drainage, they deliver dependable support and a long service life for a wide range of small-scale builds.

Where a Monolithic Slab Makes Sense

For builders planning heavy-use or high-traffic spaces, monolithic slab construction delivers long-term durability and strength. Building pole barns, equipment bays or light industrial shops that demand a solid, reinforced perimeter are some of the best use cases for monolithic slab foundations.

The continuous pour supports heavy machinery and vehicles without movement or cracking. It’s a smart choice for heated

garages or workshops where a smooth, stable surface improves comfort and performance.

How the Pennsylvania Frost Line Affects Your Build

The Pennsylvania frost line affects more than just the depth of a foundation site. It shapes the entire design, from drainage layout to insulation strategy. In colder zones, builders plan subgrade layers that allow moisture to drain and prevent frost from settling beneath the concrete.

Gravel bases, vapor barriers and thermal breaks are adjusted to match local frost depth and soil conditions. Accounting for these factors keeps the slab from flexing with temperature swings and helps preserve level flooring, tight wall connections and long-term structural alignment.

Build on a Durable, Long Lasting Slab Foundation in Central PA

A well-built foundation depends on the right design for the site and structure. In Central Pennsylvania, the choice between a floating slab-on-grade and monolithic foundation often comes down to soil, frost and load requirements.

A properly engineered slab foundation provides long-term stability, whether it’s supporting a new garage slab or a pole barn slab in Pennsylvania built for heavier use. Knowing how each foundation type performs helps you plan a base that stays solid year after year.

R. J. Potteiger Construction Services, Inc. builds concrete foundations that last. Every job receives careful planning and quality workmanship from start to finish. As a Central PA concrete contractor, we make sure your structure stays strong for decades to come.

Contact us today to schedule your evaluation and quote.